When it comes to maximizing efficiency and performance of engines, the quality of fuel plays a significant role. Diesel fuel is prone to contamination in the course of time with sediment, water and the growth of microbial. This can negatively affect engine performance and lead to costly repairs. Polishing the fuel can be utilized to prevent fuel contamination and ensure the smooth operation of engines.

The process of polishing fuel is also known as polishing diesel fuel. It involves the elimination of contaminants and impurities in diesel fuel. Professionals make use of modern equipment and techniques to restore the fuel to its optimal condition. Through the elimination of harmful substances and restoring fuel quality fuel polishing enhances engine efficiency and reduces the cost of maintenance and extends the lifespan of equipment.

Fuel polishing comes in a myriad of ways to meet the various requirements of the industries that depend on diesel. They employ highly skilled technicians who are knowledgeable about fuel systems, and can comprehend the complexities of fuel contamination. They have a deep understanding of the subject and sophisticated equipment they are able to effectively identify issues related to fuel and use the correct techniques for polishing fuel.

The main purpose of fuel polishing is to remove contaminates such as sediment, water, sludge or microbial contamination from diesel fuel. Due to leakage and condensation in tanks for fuel there is a tendency for water to build up, causing corrosion and degradation of fuel. It also encourages the growth of fungi, bacteria and other microorganisms. Sludge and sludge, on the other hand can originate from impurities in the fuel or result from the degradation of components of the fuel as they age. These contaminants may clog filters and injectors as well as other components that are essential. This can lead to lower engine performance or even breakdown.

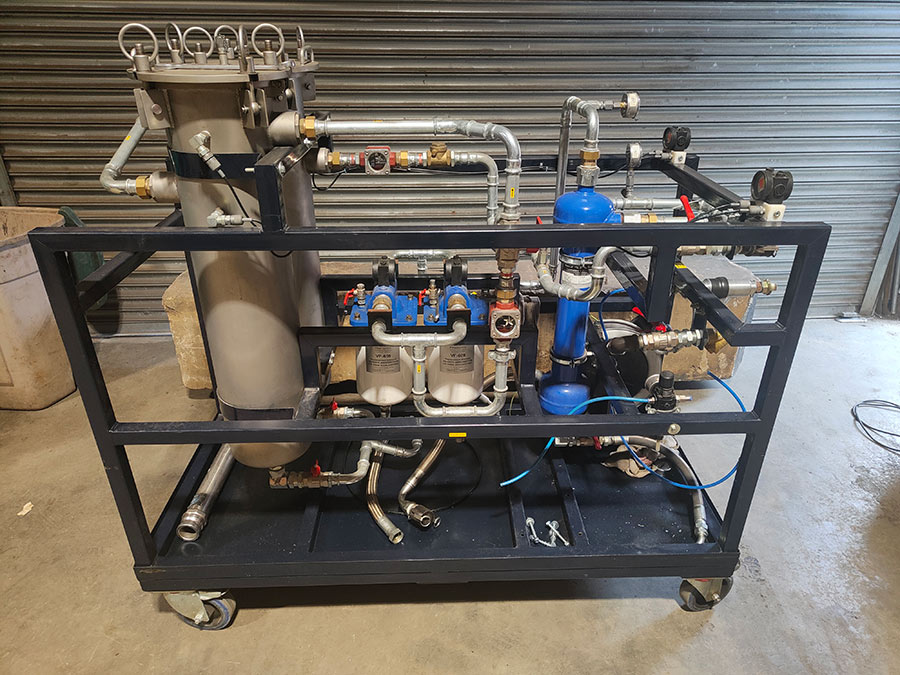

Diesel fuel polishing typically involves a multi-step process. Analyzing and sampling of the fuel is the initial step to determine the level of contamination. Following the analysis, technicians employ filtering systems to remove contaminants and impurities from the fuel. These systems utilize various filtering media and techniques to remove and separate contaminants, leaving pure diesel.

Regular fuel polishing offers several key benefits. It improves the fuel quality and ensures that engines get fresh, consistent fuel for optimal combustion. It also improves fuel economy as well as performance. This results in lower emissions as well as cost savings. Polishing the fuel also decreases the likelihood of engine breakdowns and damage caused by contaminated gasoline. Removal of harmful substances helps maintain engine health, prolonging their lifespan and decreasing repair costs.

Regular polishing of diesel fuel, also known as diesel polishing, has numerous advantages for maintaining the quality of your fuel. It helps firstly get rid of sediment, water, and microbial contaminants that can hinder the performance of engines. Diesel polishing improves fuel quality by eliminating impurities. It also enhances the efficiency of combustion and reduces emissions. Secondly, regular diesel polishing stops the blockage of fuel filters injectors, filters, and other vital components, reducing the chance of damage to engines and costly repairs. Regularly polishing fuel makes sure that the fuel storage systems last longer, by preventing the buildup of corrosion and sludge. Regular diesel fuel polishing can have a number of advantages, including better engine performance, cost reductions, and increased reliability.

Additionally, services for polishing fuel can be tailored to meet the requirements of various applications and industries. From backup generators and vessels in the marine sector to construction equipment as well as transportation fleets, fuel polishing offers a variety of solutions to deal with fuel contamination across a wide spectrum of sectors. It is especially important in industries that require a an uninterrupted and stable power supply, and industries operating in remote or harsh environments where fuel quality is at risk.

Fuel polishing, in summary is a crucial process to ensure the quality and cleanliness of diesel fuel. In removing impurities, contaminants, and pollutants and reducing engine efficiency, it increases the effectiveness of the engine and reduces the cost of maintenance and extends the lifespan of the equipment. When investing in professional fuel polishing, industries can safeguard their operations, improve performance, and lower the risk that comes with contamination of the fuel. Fuel polishing can unlock the potential of diesel fuel, allowing you to drive your business forward.